|

|

|

|

- I'm Online Chat Now

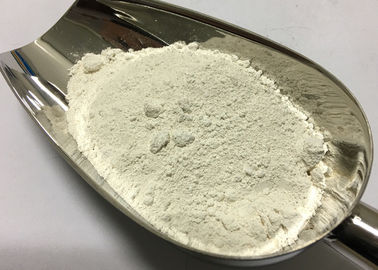

Fine CeO2 Cerium Oxide Glass Polishing Compound 0.8-1.3μM For Optical Equipments

Product Details:

Payment & Shipping Terms:

|

Detailed Product Description

| Appearance: | White Powder | Purity: | 99.95%Min |

|---|---|---|---|

| Size: | 0.8-1.3μm | EINECS: | 215-150-4 |

| Density: | 7.132 | Molecular Formula: | CeO2 |

| High Light: | cerium oxide poeder,cerium oxide glass polishing powder |

||

High Speed Fine CeO2 Polishing Powder 0.8-1.3μm for different glass and optical equipments

Polishing ability

The polishing ability of the rare earth polishing powder and the content of cerium oxide and the physical and chemical properties of the polished powder are closely related to the viscosity and chemical activity. The rare earth polishing powder with high cerium oxide content is highly polished, but the price of cerium rare earth polishing powder is expensive, and the low cerium rare earth polishing powder is widely used. In the process of making rare earth polishing powder, additives containing fluorine and sulfate are usually added to make fluoride and sulphate. Rare earth polishing powders containing fluoride and sulphate generally have good polishing performance. For example, the average content of cerium oxide in XP-771 and XP-CF rare-earth polishing powders commonly used in China is only 50%, but they all contain fluoride and [2] of sulfate root.

classification

The specifications and models of rare earth polishing powders in various countries are different, and they can be divided into three types, cerium, cerium and cerium according to the content of cerium oxide. China according to the preparation of different rare earth polishing powder consists of oxalate and sulfate (including salt), fluorocarbonate three system.

application

Compared with Fe2O3, Al2O3 and other abrasive materials, rare earth polishing powder has the advantages of fine granularity, good chemical activity, strong grinding capability and long service life, widely used in optical glass components, TV kinescope glass, glasses, glass plate, tube and organic glass products polishing [3].

expectation

The production process of rare earth polishing powder has been basically finalized, and has been widely used in industry. The consumption of the rare earth polishing powder is more than 4000t in the world. Since 1980s, China has made use of its rich rare earth resources to produce rare earth polishing powder on a large scale. It is used in many industrial sectors. With the rapid development of color TV and electronics industry, the demand for rare earth polishing powder in China will increase in the next few years.

The polishing ability of the rare earth polishing powder and the content of cerium oxide and the physical and chemical properties of the polished powder are closely related to the viscosity and chemical activity. The rare earth polishing powder with high cerium oxide content is highly polished, but the price of cerium rare earth polishing powder is expensive, and the low cerium rare earth polishing powder is widely used. In the process of making rare earth polishing powder, additives containing fluorine and sulfate are usually added to make fluoride and sulphate. Rare earth polishing powders containing fluoride and sulphate generally have good polishing performance. For example, the average content of cerium oxide in XP-771 and XP-CF rare-earth polishing powders commonly used in China is only 50%, but they all contain fluoride and [2] of sulfate root.

classification

The specifications and models of rare earth polishing powders in various countries are different, and they can be divided into three types, cerium, cerium and cerium according to the content of cerium oxide. China according to the preparation of different rare earth polishing powder consists of oxalate and sulfate (including salt), fluorocarbonate three system.

application

Compared with Fe2O3, Al2O3 and other abrasive materials, rare earth polishing powder has the advantages of fine granularity, good chemical activity, strong grinding capability and long service life, widely used in optical glass components, TV kinescope glass, glasses, glass plate, tube and organic glass products polishing [3].

expectation

The production process of rare earth polishing powder has been basically finalized, and has been widely used in industry. The consumption of the rare earth polishing powder is more than 4000t in the world. Since 1980s, China has made use of its rich rare earth resources to produce rare earth polishing powder on a large scale. It is used in many industrial sectors. With the rapid development of color TV and electronics industry, the demand for rare earth polishing powder in China will increase in the next few years.

Rare earth polishing powder has the advantages of fast polishing speed, high finish and long service life. Compared with traditional polishing powder - iron red powder, it is easy to remove the advantages from the contamination.Polishing the lens with cerium oxide, the amount of work done in one minute, such as polishing powder with iron oxide, takes 30 to 60 minutes.Therefore, rare earth polishing powder has the advantages of low dosage, fast polishing speed and high polishing efficiency.And can change the polishing quality and the operating environment.Common rare earth glass polishing powder mainly USES cerium oxide.Cerium oxide is a highly effective compound for polishing because it can be used in both chemical and mechanical friction to polish the glass at the same time.Rare earth cerium polishing powder is widely used in the polishing of camera, camera lens, television picture tube, eye lens, etc.

Certificate Of Analysis

| ITEM | SPECIFICATIONS | TEST RESULTS |

| Appearance | White Powder | White Powder |

| Purity(%,min) | 99.5 | |

| TREO(%,min) | 95.29 | |

| La2O3/TREO(%,min) | 66.56 | |

| CeO2/TREO(%,min) | 33.44 | |

| RE Impurities(%/TREO,Max) | ||

| Nd2O3 | 0.01 | |

| Sm2O3 | 0.01 | |

| Eu2O3 | 0.01 | |

| Gd2O3 | 0.01 | |

| Tb4O7 | 0.01 | |

| Dy2O3 | 0.01 | |

| Ho2O3 | 0.01 | |

| Er2O3 | 0.01 | |

| Tm2O3 | 0.01 | |

| Yb2O3 | 0.01 | |

| Lu2O3 | 0.01 | |

| Y2O3 | 0.01 | |

| Non-Re Impurities(%,Max) | ||

| Fe2O3 | 0.01 | |

| Na2O2 | 0.16 | |

| CaO2 | 0.063 | |

| Cl- | 0.01 | |

| F- | 4.60 | |

![]()

![]()

Contact Details

Changsha Easchem Co., Limited

Contact Person: andrew.liao

Send your inquiry directly to us

More Cerium Oxide Powder

-

Rare Earth Cerium Oxide Polishing Powder 0.1-0.5um 0.4-0.8um Cas No 1306-38-3

-

3500 ºC Boiling Point Cerium Dioxide Powder / Cerium Oxide Glass Polishing Compound

-

Optical Grade Cerium Oxide Powder / Cerium Oxide Polishing Compound For Glass Industry

-

High Temperature Stability Cerium Oxide Glass Polishing Powder Improve Efficiency

-

20.0 - 30.0μM Cerium Dioxide Powder 2600ºC Melting Point Molecular Weight 172.1148

-

Rare Earth Cerium Oxide Powder Eliminate Contamination Environment Arsenic